The backflow flap for mechanical extract ventilation systems is the solution for air exchange without energy loss since it makes sure that no warm air escapes through the ventilation duct and no cold air penetrates into the building.

Service: +49 2363 / 9123-0

The backflow flap for mechanical extract ventilation systems is the solution for air exchange without energy loss since it makes sure that no warm air escapes through the ventilation duct and no cold air penetrates into the building.

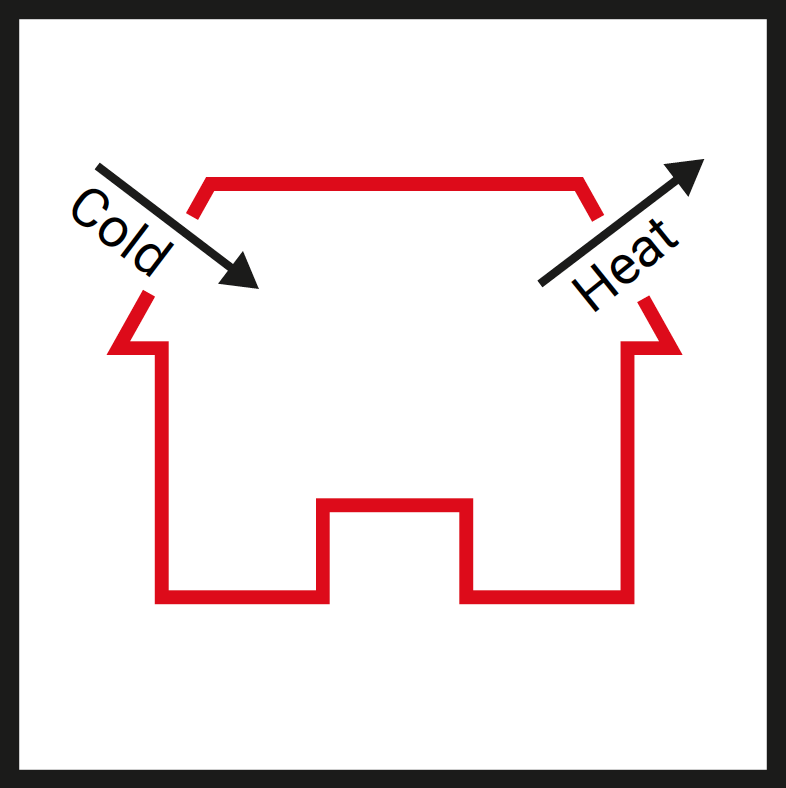

When “energy waste” is mentioned, the majority of Germans automatically think of electricity first. Yet most of the energy produced in the home is wasted mainly by the loss of heat. Especially owners who have equipped their houses with ventilation systems, e.g. in the bathroom or kitchen, risk energy losses due to unwanted air exchange.

No more energy loss through ventilation ducts

A backflow flap within the ventilation duct prevents cold air from entering it in the winter or prevents warm air from escaping in an uncontrolled way. Use of a backflow flap is possible and useful in all mechanical extract ventilation systems. These are mainly installed in rooms that are not (cannot) be ventilated continuously – for example, in inner-lying bathrooms* – or in those in which a large amount of exhaust air is produced within a short time, which must then get outside, like when cooking in the kitchen. It is also advisable to install backflow flaps in vents and terminals on the flat roof, as the air ducts to the outside are shorter there than on the pitched roof and cold air can therefore get into the inside of the building faster.

Other advantages of a backflow flap at a glance

*Please note that backflow flaps are not suitable for use in wastewater pipes or so-called stack ventilation or odour reduction.

The backflow flap can also be integrated into the tried and tested FLECK “Sani Extra” pitched roof ventilator.

At FLECK, the backflow flap is optionally integrated into the ventilator during production. Adaptation to the existing roofing or waterproofing is made possible by the individualisation: In the pitched roof segment, FLECK can produce the vent or ventilator for almost 300 roof tile models and paints them in the colour of the existing clay roof tile or concrete roofing tile. In the flat roof segment there is a large choice of suitable waterproofing materials in the form of flange collars made of bitumen or plastic and elastomeric roofing membranes.

Integration in the factory is possible for the following vents:

At FLECK your contact will always support you on site.

Find your personal contact now and arrange an appointment for a product presentation.

Our field sales and sales office team is available to answer your questions at any time.