General

According to DIN 18531-3, Clause 7.8, an extension is the component for backwater-safe bridging of the thermal insulation. The waterproofing sheet is joined watertight on the extension. According to this standard, with the roof drain, a two-part roof system (warm roof) is made. Two-piece drains are therefore mostly used for thermally insulated flat roofs.

For two-piece drains in flat roofs, the terms base elements, bases, drains, extension are at times used synonymously “on the market”, but they are also interpreted or used in different ways.

In addition to the above passage from DIN 18531, EN 1253-2 notes:

“Two-piece roof drains shall have a tight connection between the drain (outlet) and the add-on element.”

The setup of a two-piece drain with extension with regard to the FLECK products is as follows: either a flat roof drain or a flat roof gully or a flat roof body is installed in the vapour retarder level and is joined airtight with the vapour retarder (bituminous or plastic).

In this condition the installed products operate like a drain and can drain roofs reliably during the construction phase before the flat roof has been completely insulated and sealed. This means that – regardless of the designation – this component installed in the vapour barrier level must first function as a drain.

If the flat roof is then fitted, for example, with insulation and roof waterproofing is laid on top of it (bitumen or plastic or elastomeric roofing sheet), this additional build-up must be supplemented with a so-called extension. The extension bridges the insulation level and in turn performs the function of an “extendable” flat roof drain. The extension generally has a piece of pipe that can be shortened and is inserted in the existing FLECK flat roof drain or FLECK flat roof gully or the FLECK flat roof body. To connect the thus-formed two-piece flat roof drain, vapour and watertight, the two components can either be bonded or they are protected by a FLECK flat roof body with backflow seal.

Summing up: All FLECK flat roof drains, FLECK flat roof renovation drains and FLECK flat roof gullys are basically suitable extensions, which are installed in existing drains, gullies or base elements and thus form an extended two-piece drain in the flat roof in order to bridge the insulation level safely.

In the event of a FLECK flat roof gully that has been installed in the vapour retarder level, note that the pot diameter corresponds to a DN 150 pipe and is therefore a FLECK flat roof drain DN 150 is added to it to increase the height (Important: Do not forget the bonding, as the gully does not have a backflow seal).

The FLECK roof accessories include an extensive range of complementary products for the roof trade. The products are produced for pitched roof, flat roof and solar applications. They include, among other things, completely assembled tile systems for ventilations, penetrations, roof access, snow guard systems, photovoltaic and solar heat systems and suitable accessory parts. The flat roof vents, feedthroughs, gullies and drains, inspection chambers fitted with individual flanges and appropriate complementary accessories, such as the unique ROOFGUARD leaf screen, make it easier to construct safer flat roofs.

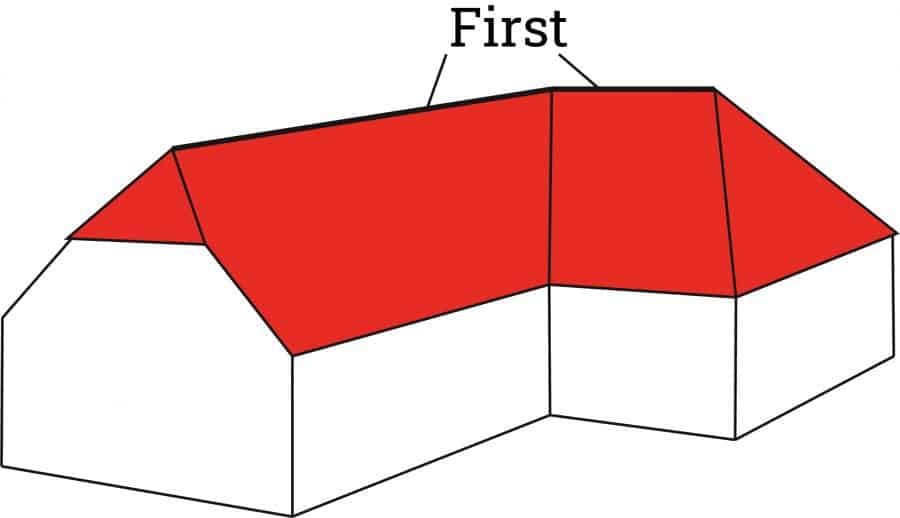

The roof ridge (ridge for short) is the term used for the top, generally horizontal, end of a pitched roof. At this point of a pitched roof, for example, the two sloped roof surfaces meet. On tiled roofs the ridge cover mostly consists of half-round ridge tiles made of clay or concrete, which provide rainproof cover for the top ends of both sloped roof areas. On older tiled roofs, the ridge tile was frequently laid in mortar. Modern ridge solutions can be fixed with clips and equipped with special ridge elements. They provide ventilation options for the roofs along the whole ridge, the highest point on the roof. Air can therefore flow from the eaves to the ridge. The ridge is generally horizontal, however, in exceptional cases it can also be sloped and should not be confused with the so-called hip.

Flat roof base elements are used to pass through ventilation ducts, drainage pipes and other penetrations, for example, through ceilings made of concrete. The one-piece FLECK base elements consist of a stable flange and a connecting pipe in diameters DN 50 – DN 500. Flat roof base elements form a precise-fitting base for extensions, roof drains, gullies, vents and ventilators, and goosenecks in the corresponding diameters.

Two variants are available to choose from:

- Base elements for bonding the attached pipes of vents, drainage or penetrations

- Base elements with integrated backflow seal, for simplified installation (without bonding!) of the attached vents, drainage and penetrations

Information on the product can be found here.

A flange is commonly used to describe a ring-shaped disc with the help of which pipes are joined together. In general, this ring is permanently attached to the end of a pipe. The two pipes are then joined by bolts, which are inserted through holes in the adjacent flanges, and nuts.

Based on this, FLECK calls the foot or baseplate of its flat-roof products a flange. FLECK products have flanges in diverse sizes and shapes and are used for secure support on level surfaces such as flat roofs. Tapered holes in the flange make it easier to fasten them securely on the surface. A flange enables proper connection of vapour retarders and roofing sheets. The technical information of the sheeting and roof waterproofing material manufacturers must be noted. The flange can have collars already attached by FLECK in the factory and made of the most common roof waterproofing materials (bitumen, plastic and elastomeric roofing sheets).

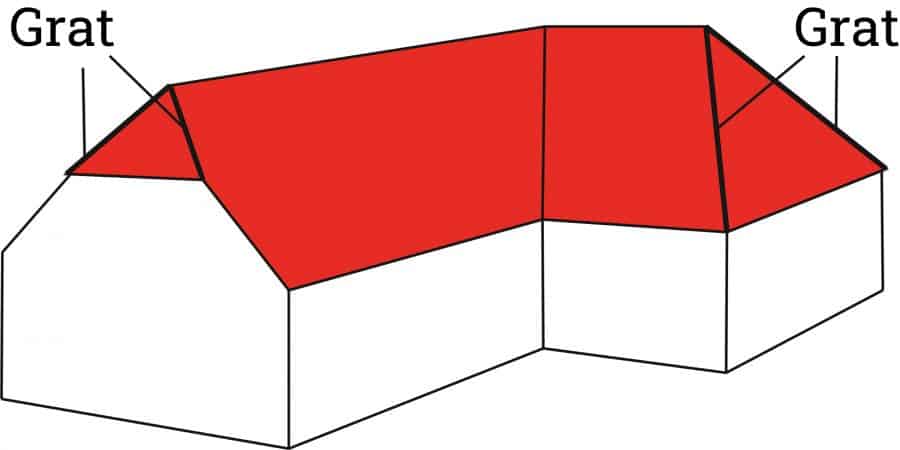

The hip is formed by the upper connecting line of two adjacent sloping sides of a roof that meet with a downward slope. They are classically found on hip(ped) roofs, mansard roofs, pyramid hip roofs, jerkinhead roofs and dormers. At a hip, the cover at the ridge is mostly made of half-round clay or concrete ridge tiles, which provide rainproof cover for the top ends of both sloped roof areas. These can be set in mortar or fixed with clips. The counterpart of a hip is the bottom sloped connecting line between two sloped roof areas, which is called the valley.

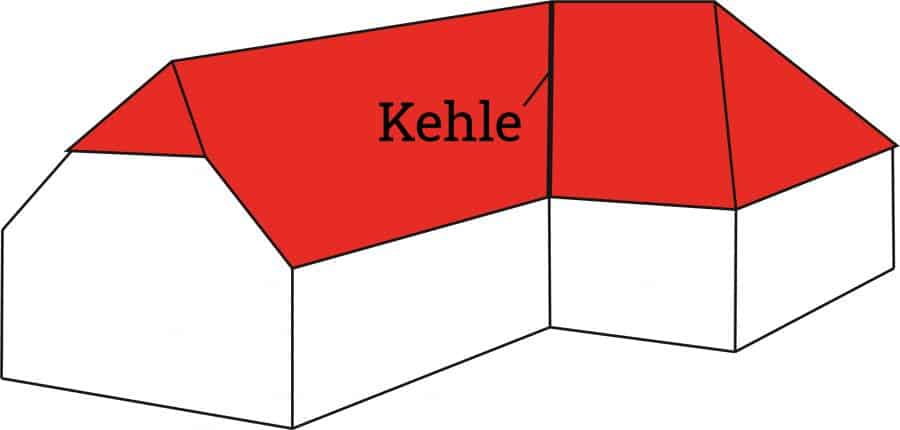

The valley forms the counterpart to a hip. It is the bottom inclined connecting line between two pitched roof areas. Water running off the meeting roof areas is guided along this connecting line in the direction of the eaves or roof gutter via appropriately adapted valley flashing.

FLECK inspection chambers are used on thermally insulated flat roofs. They enable fast inspection of the insulation layer, without having to open the flat roof waterproofing. Penetrated water or increased moisture content are quickly identified in an inspection chamber. Inspection chambers are offered as a two-piece solution (slotted base element + inspection chamber), as well as a one-piece solution e.g. for subsequent installation.

To minimise thermal bridges, FLECK uses a stable EPS insulation core in the thermal conductivity group WLG 040, which can be removed for inspection, in the inspection chambers for insulated flat roofs.

Note: In Austria, inspection chambers as defined in ÖNORM B 3691 are specified for roofs in use category K3.

In general technical usage, a collar is a jacket surround, for example, for protection, stabilisation or separation of an item. As a pipe coupling (“collar seal”), they can also be used for tight connection between two systems.

Based on this, FLECK collars are generally made of bituminous membrane or plastic and elastomeric roofing sheets. These are used by FLECK for flat roof products with a flange. The collars are permanently joined with the flanges in the factory and make it easier for the roofer to make the proper joint on the respective roofing sheets present on site.

Due to the large number of roof waterproofing materials offered on the market, FLECK provides a wide choice of appropriate collars. This especially applies to the plastic and elastomeric roofing sheets based on the wide range of materials available on the market. Common PVC, PIB, ECB, EVA, EPDM and FPO-based plastic and elastomeric roofing sheets available for waterproofing are produced by calendering or extrusion. They involve the following materials:

- ECB (ethylene polymer bitumen)

- EPDM (ethylene propylene diene terpolymer)

- EVA/EVAC (ethylene vinyl acetate terpolymer/copolymer)

- FPO (flexible PE or PP-based polyolefin)

- PIB (polyisobutylene)

- PVC-P (Polyvinyl chloride, bitumen-compatible bv or non-bitumen-compatible bn)

- TPE (thermoplastic elastomers)

Information on the possible products and flange and collar types can be found here.

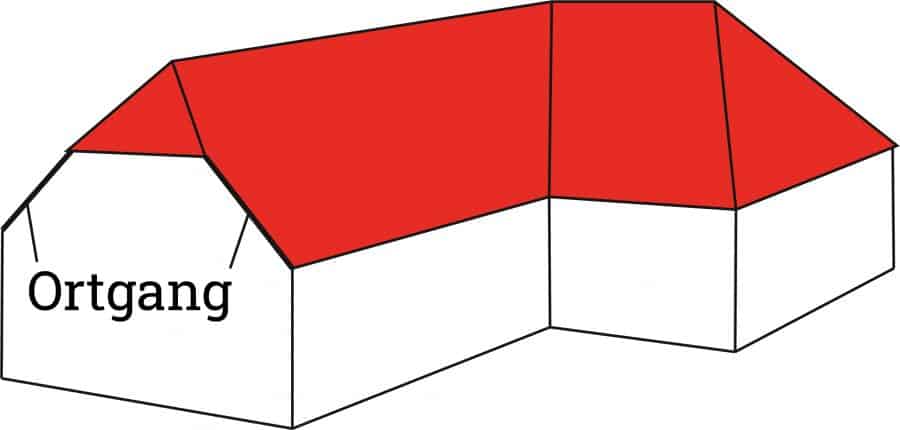

Verge is the name used to describe the edges of the roof on the gable side. They form the side end of a roof along the gable. This is where the roof truss, the roof covering and the gable meet. The verge area is considered to be very sensitive, as if the work is not carried out properly, it can allow the ingress of moisture and unwanted airflows. To prevent this, measures must be taken at the verge, which meet the thermal insulation, air tightness, windtightness, rain protection and wind suction protection requirements.

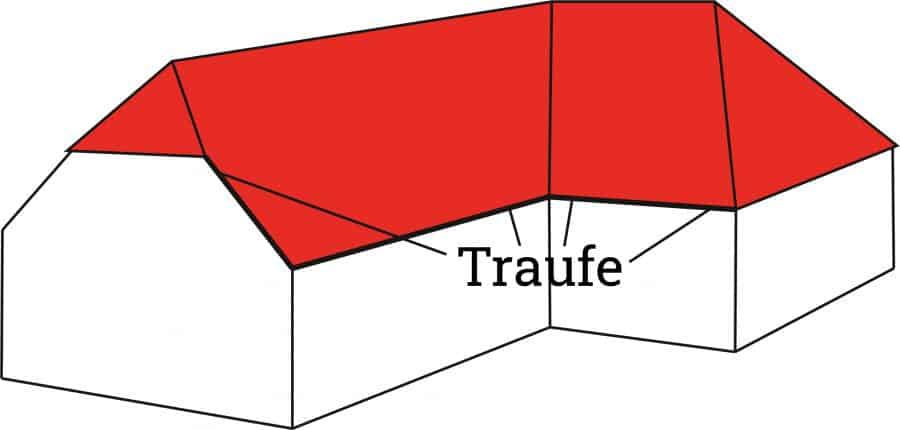

The roof eaves, or eaves for short, is the name used to describe the bottom “drip profile” on the sloped roof of a building. The collected rain water flows over the eaves. A gutter is frequently attached to the end of the eaves, which catches the water and safely discharges it. The roof area located between the external wall of the building and the eaves is also called the roof overhang. The eaves are the bottom boundary of the roof. The upper boundary is called the roof ridge and the side boundaries, the verge. Hip and valley, represent further limiting lines in the roof area.

WLG describes the thermal conductivity group of thermal insulation materials. The thermal conductivity groups are graduated in increments of 0.005 W/(mK)*, i.e. WLG 035, WLG 040, WLG 045 etc. The smaller the WLG value is, the better the thermal insulation property.

The assignment of a thermal insulation material to a WLG is always determined from the first three places after the decimal of the thermal conductivity “λ”. The thermal conductivity “λ” is generally given in W/(mK). Thermal insulation materials with a λ –value of 0.036-0.040 W/(mK) are then assigned to the WLG 040 class.

To minimise thermal bridges, FLECK uses a stable EPS insulation core in WLG 040, which can be removed for inspection, in the inspection chambers for insulated flat roofs.

*W = Watt, m = metre, K = Kelvin

Roofing sheets

Sheets for waterproofing unused and used areas must be suitable for the intended use and must be matched to each other and the waterproofing underlay. The materials suitable for the waterproofing of roofs in the respective individual case and the appropriate layer build-up of insulation and waterproofing must be defined when designing the roof. Roofing sheets can be roughly differentiated into the two following groups:

- Plastic and elastomeric roofing and waterproofing sheets (membranes)

- Bitumen sheets

Based on a wide range of materials and different properties, plastic and elastomeric roofing and waterproofing sheets offer diverse possible uses. Produced by calendering or extrusion, common plastic and elastomeric sheets available for waterproofing are based on the following materials:

| Sheet material: | Composition: | |

| ECB | Ethylene copolymer bitumen | |

| EPDM | Ethylene propylene diene terpolymer | |

| EVA/EVAC | Ethylene vinyl acetate terpolymer/copolymer | |

| FPO | Flexible polyolefin (PE or PP-based) | |

| PIB | Polysobutylene | |

| PVC-P | Polyvinyl chloride (bitumen-compatible bv or non-bitumen-compatible nb) | |

| TPE | Thermoplastic elastomers |

This waterproofing therefore offers a large variety of materials and therefore covers a wide range of uses. Laid loosely, mechanically fixed or completely bonded, they are used in new build and for repair. The manufacturers’ ranges include sheets from 1.2 mm to over 2.5 mm thick. Apart from many other uses, plastic sheets are also suitable for safe and environmentally friendly waterproofing of green roofs.

ECB is the material designation for a black-coloured mixture based on high-quality polyethylene copolymers with varying fractions of special and different amorphous bitumen qualities. Pure bitumen of one type is homogeneously embedded in the polymer matrix and can therefore be processed as a free-flowing granulate (pellets) in conventional plastic processing plants. In ECB, the positive properties of polyolefins are united with bitumen. Due to its good viscosity, ECB is characterised by high biaxial resistance to strain and flexibility, even at low temperatures. Special stabilisation lends ECB excellent resistant to heat ageing and UV radiation. ECB is not only largely weather and ageing resistant but is also thermostable.

EPDM is one of the synthetic rubbers with a saturated main chain, they have double bonds in the side chains and can therefore be vulcanised with sulphur. The rubber-elastic material EPDM is used in diverse ways by industry, e.g. for profiles in automotive and apparatus manufacture, for conveyor belts, hoses for washing machines and dishwashers, seals for water fittings, for cable sheathing, etc. In buildings, EPDM waterproofing sheets are used to waterproof roofs and façades or as pond liners for waterproofing membrane ponds (swimming ponds and water basins). The material is widely used wherever robust waterproofing materials that are resistant to UV, ozone, acid and mechanical exposure are needed. In 1968, the first flat roof in Europe was waterproofed with EPDM.

EVAC, previously also EVA, are copolymers made of ethylene and vinyl acetate. They are available as pellets, aqueous dispersion, powder, as well as film material. The plastic has high thermal and good ageing resistance. However, the properties and possible uses can be varied greatly with the proportion of copolymerised vinyl acetate. Vinyl acetate fractions up to 7 % are almost exclusively used to improve the properties of films (in particular, increasing their elongation at break). Around half the EVAC produced is manufactured with less than 7 % vinyl acetate. EVAC, with a vinyl acetate fraction of 7 to 18 %, is often also used an exclusive material for special applications. Examples are cold-resistant, pull-out pourers (spouts) of canisters, sheeting for agriculture and gardening, shrink-wrap films (office supplies, solar modules), shower curtains, floorings, roofing sheets and electric cables. In photovoltaics, solar cells are embedded in EVAC. Here the EVAC used in films is melted at temperatures around approx. 150 °C, becomes glass-clear and cross-links three-dimensionally. After cooling, a permanent compound exists, which protects the cells from environmental influences.

Roofing sheets made from thermoplastic polyolefin (TPO) belong to the group of plastic waterproofing systems and consist of alloys of different individual plastics such as polyethylene, polypropylene and polybutylene as well as integrated reinforcement. Various associations and manufacturers also call them flexible polyolifins (FPO), because they are significantly less stiff than, e.g. polyethylene. They are characterised by their good chemical resistance and electrical insulation properties. FPO (PE) are used to produce, among other things, sheeting, films, blown films (bubble wrap), shrink-wrap films, heat-shrink tubing, coatings and packaging. FPO (PP) is used, among other things, as packaging in the medical and in the food sector, for fibres and pipes.

PIB was first produced in 1931 by the Badischen Anilin- und Sodafabrik (BASF SE) in Ludwigshafen-Oppau and was marketed under the trade name Oppanol. PIB can be used in solutions and dispersions for coating. In addition, similar to natural rubber, it can also be processed in rolling mills, in kneading machines, presses, by calendering and extruding. The processing temperature lies between 150 °C and 240 °C. Other applications are sealing compounds, wax admixtures for lining and coating, plaster adhesive and spray plasters, fly trap adhesive on yellow stickers, raw mixture for producing chewing gum, roof waterproofing sheets (membranes), mixtures with polyolefins for improving workability and plasticising explosives such as PETN or hexogen. Polyisobutylene is also used as an additive in other plastics, e.g. in butyl rubber mixtures and as lubricant additive.

Polyvinyl chloride is a thermoplastic polymer, which is produced from the monomer vinyl chloride by chain polymerisation. After polyethylene and polypropylene, PVC is the third most important polymer for plastics. The PVC plastics are divided into hard (rigid) and soft PVC. Rigid PVC is used, for example, to produce window profiles, pipes and records. Soft PVC contains additives which lead to the elastic behaviour of the material. For example, it is used for cable sheathing and floorings. PVC can be easily coloured and absorbs hardly any water. It is resistant to several acids and alkalis and is conditionally resistant to ethanol, oil and benzine. The advantage of PVC is its durability. Sunlight does not cause it to decompose, the mechanical properties are not impaired. Water (including salty seawater) and air can hardly damage or destroy PVC or not at all. PVC is therefore mainly used for long-life products. The products can be produced in all kinds of different colours and decorative finishes (decors). PVC sheeting has different applications, e.g. for the water cores of water beds, as synthetic leather or for film sheets/pockets in stamp albums, as pond liners and roofing sheets in the construction sector and for floorings.

Thermoplastic elastomers are plastics that behave comparably with classic elastomers at room temperature, however, can be deformed plastically when heat is added and therefore display thermoplastic behaviour. Thermoplastic elastomers are materials in which elastic polymer chains are integrated in thermoplastic material. They can be processed in a purely physical process in combination with high shear forces, the action of heat and subsequent cooling. Although chemical cross-linking by time-consuming vulcanisation at high heat, as with elastomers, is not necessary, the parts made have rubber-elastic properties due to their special molecular structure. Renewed heat and shear force action leads to the melting and deformation of the material. At the same time, however, this means that the TPEs are far less able to withstand thermal and dynamic exposure than standard elastomers. The TPEs are therefore an addition that combine the advantages of thermoplastics with the material properties of elastomers. A large advantage of these elastic plastics is the possibility of welding them in order to generate watertight connections.

Bitumen sheets are sheets with carriers and bitumen overlays on both sides. They are usually differentiated into:

Bituminous membrane

- PYE elastomeric bitumen (bitumen modified by the addition of thermoplastic rubbers)

- PYP plastomeric bitumen (bitumen modified by the addition of polyolefin or polyolefin copolymer compound)

- PYE/PYP combination of elastomeric and plastomeric bitumen

Self-adhesive sheets

- KSP self-adhesive reinforced polymeric bitumen sheet

- KSK self-adhesive bitumen waterproofing membrane with HDPE carrier film

PYE elastomeric bitumen (bitumen modified by the addition of thermoplastic rubbers)

Elastomeric bitumen sheets are made from straight-run bitumen (primary bitumen) which is modified with SBS (styrene butadiene styrene) (elastomers). With increasing SBS fraction, the bitumen acquires a rubber-like behaviour, whereby the rubber added can be up to 20%. However, as a higher rubber fraction makes laying and melting the sheets more difficult, most bituminous membranes are made with particularly meltable overlays on the underside of the sheet. The advantages of this type of sheet are its low temperature sensitivity, good thermal stability and very good flexibility at low temperature, the distinct elastic behaviour as well as a long life with high weather and ageing resistance.

PYP plastomeric bitumen (bitumen modified by the addition of polyolefin or polyolefin copolymer compound)

Plastomeric bitumen sheets are made from straight-run bitumen (primary bitumen) which is modified with APP (atactic polypropylene) (thermoplastics). Plastomeric bitumen membranes come from the Mediterranean, where they have been used for decades, particularly due to their high thermal stability: They endure decades of exposure to sunshine without visible change and without loss of their sealing function. The advantages of this type of sheet are its extraordinary thermal stability and good flexibility at low temperature, its plastic behaviour which simultaneously lends the sheet high 2-dimensional stability, a long life with high weather and ageing resistance as well as very easy fusibility. Plastomeric bitumen sheets are generally produced as membranes and are laid using torch-on methods. The plastic fraction of the highest-quality membranes is up to 40% of the bitumen fraction; plastomeric bitumen membranes with small plastic fraction tend to be more like elastomeric bitumen membranes.

PYE/PYP combination of elastomeric and plastomeric bitumen

PYE/PYP combinations achieve improved bending behaviour at low temperatures as well as increased flexibility at low temperature – in combination with polyester felt and combination carriers both elastomeric bitumen and plastomeric bitumen sheets acquire excellent mechanical properties (tensile behaviour, extensibility and resistance to perforation).

KSP self-adhesive reinforced polymeric bitumen sheet

Self-adhesive sheets are polymer bitumen sheets to which a self-adhesive coating is applied on the underside in the factory; after pulling off a release film or release paper, the self-adhesive side can be laid on a self-adhesive-compatible substrate by applying pressure (cold application without torching). The underside overlay is given a self-adhesive finish in the factory. This means that the sheet can be bonded without applying strong heat. Thermal activation, especially in cool outdoor temperatures, is nonetheless recommended by many manufacturers.

KSK self-adhesive bitumen waterproofing membrane with HDPE carrier film

KSK bitumen sheets are a means of waterproofing structures (English tanking, German “black tank”). They consist of plastic-modified bitumen, which is applied on a tear-proof HDPE carrier film. They are suitable for the load cases of soil moisture and non-accumulating seepage water load cases. Self-adhesive sheets (KSK sheets) bridge cracks in the masonry and are resistant to cold and heat. The sheets can be loaded immediately after bonding. More expensive in material costs than bituminous membrane, the advantage of the self-adhesive bitumen waterproofing sheets is their shorter application time. The self-adhesive membrane is rolled out over the whole surface, overlapping and crease-free, whereby the protective layer is pulled off. The sheets may also be laid at slightly below-zero temperatures.

Roof shapes

A flat roof is usually the term used to describe a roof with a roof pitch of less than 10 degrees. With the “New modernity” and the increasing popularity of linear design after Bauhaus, the flat roof became an increasingly important roof shape. Due to the low to non-existent roof pitch, flat roofs must be built with watertight roof waterproofing to protect them against standing and penetrating water. Adapted. prefabricated accessory parts are an advantage for safe penetration of the roof waterproofing.

The roof shape found most widely in Europe is the saddleback roof, more commonly called the gable roof in English, which consists of two opposite pitched roofed areas. Also called a gable roof or ridged roof. Gable roofs can have different forms and are subject to a simple design principle. In its basic form, the saddleback roof (more commonly called the gable roof) is a roof shape tried and tested for hundreds of years. And yet the gable roof changes repeatedly because architects like to leave behind their mark or thumbprint in the shape, colour and choice of material. Examples can be found at www.DACHKULT.de.

Pitched roof is the name given to roofs with a pitch of more than 20° degrees. The pitched roof is one of the most popular roof shapes in Germany. The top end of the pitched roof is called the ridge – the opposite of which is formed by the eaves, because they represent the bottom end of the roof. Pitched roofs need adapted systems for ventilation, water routing and discharge, for safeguarding them against snow loads, for access and for the installation of penetrations or additional roof structures, such as solar systems. The FLECK pitched roof-accessories now include several thousand efficient articles.

Roof constructions

A green roof is the name given to a flat roof or a pitched roof, which is planted with vegetation. The vegetation is placed directly above the protective felt on the roof waterproofing layer and provides several building physics and ecological advantages: The plants form natural protection for the roof waterproofing, compensate for extreme temperatures and thus shield against environmental influences. This reduces the impact on the waterproofing appreciably. Nonwoven or felt and plant substrate form a natural water store, which retains rainwater and allows it to flow away slowly after a delay.

When planting a roof, a differentiation is made between an extensive and an intensive green roof. On an extensive green roof, natural vegetation forms with low growth form are primarily chosen, such as moss or grasses. These types of plants rarely need watering and also withstand high temperatures. So-called roof gardens with perennial plants and even trees also fall under intensive green roofs. They require far more maintenance, as the plants must be watered and fed regularly, which is why intensive green roofs should also be accessible at all times. Intensively planted flat roofs are frequently built as an inverted roof, a special system for insulating flat roofs.

To enable the flat roof drainage points to be maintained regularly, it is advisable to install the FLECK green roof chamber as an inspection facility above a drain or gully. The green roof chamber is equipped with a removable weather cap, which allows fast maintenance and inspection.

The term “industrial roof” is not generally defined in construction. It mainly describes flat roofs of hall-type buildings with large dimensions, whose substructure is made of trapezoidal steel sheet.

A more precise differentiation can be made with the German industrial building guidelines (“Industriebaurichtlinie”, IndBauR) and their fire protection requirements as well as DIN 18234: “Baulicher Brandschutz großflächiger Dächer – Brandbeanspruchung von unten” (Fire safety of large roofs for buildings – Fire exposure from below). These specify the arrangement of fire compartments for a roof area of more than 2,500 square metres. DIN 18234 also defines, e.g. the roof structure (build-up), the execution of penetrations and the type of corrugation fill, i.e. the elements used to fill (insulate) and seal the corrugations in corrugated sheets.

A cold roof is a roof structure ventilated above the insulation layer. The insulated level is arranged so that air can circulate between the insulation and the roof waterproofing. The ventilated area is primarily used to remove the moisture diffusing through the roof layers and thus prevent condensation in the roof structure. FLECK eaves elements with proper supply air cross-section and the unique FLECK Europa eaves tape enable proper construction of pitched roofs in the area of the eaves. The opposite of a cold roof is a warm roof, in which the additional ventilation area between the insulation and roof waterproofing can be omitted.

A solar roof – also called an energy roof – produces heat or electricity solely from the sun’s energy. To this end, a solar heat system or photovoltaic system (array) is installed on the pitched roof or flat roof. On a pitched roof, both systems are installed either above the roof tile or as in-roof photovoltaic arrays or with solar roof tiles.

A photovoltaic system (array) converts sunlight into electricity. The situation in a solar heat system is different: It uses heat acquired from the solar energy to heat heating or domestic water. A solar roof can be installed on both a flat roof and on a pitched roof, it is climate-friendly and also economically very lucrative, as the solar energy is free. House owners and builders who switch to solar energy in new build or as part of a modernisation project can often make use of grants to help pay for the costs. Further information is available from the Bundesverband Solarwirtschaft e. V..

FLECK offers solar accessories that are easy to install pitched roof products such as the solar feedthrough tiles or the solar support tiles, which enable the photovoltaic or solar heat system to be installed properly. Feedthrough solutions for cable and pipe penetrations on a flat roof are available to installers, such as our FLECK goosenecks up to DN 300 (bundling of pipes or cables) and our Schrumpfis (individual pipes/cables).

A special system for insulating flat roofs is the so-called inverted roof. Unlike the conventional method in which the roof layer is protected from above by waterproofing, here a water-resistant insulation material, which is laid as a single layer or multiple layers and free from thermal bridges, is more highly exposed to the outdoor weather.

On an inverted roof the waterproofing – mostly a bitumen or plastic sheet – is located under the insulation boards. In general it is laid directly on the load-bearing structure of the flat roof, for example, on the top reinforced concrete ceiling of the building.

The insulation, on the other hand, is not waterproofed, but is covered from above with a felt and covered, for example, with a loose gravel fill or a green roof build-up and is thus protected against wind suction effects. On an inverted roof, the insulation boards are usually laid loose. However, the gravel does not protect against moisture due to rain or snow. The same also applies to the felt or nonwoven. This is primarily intended to prevent parts of the gravel fill from trickling into the insulation level and, for example, accumulating in the joints between the insulation boards. The felt is therefore water-permeable, at least on the conventional inverted roof.

As the insulation lies within the frequently wet outer area, only materials that are resistant to moisture can be used. Inverted roofs are very often made with extruded polystyrene (XPS) rigid foam. It absorbs very little water and is also considered to be rot-resistant. However, XPS is not UV-resistant, which is why, for example, the gravel ballast is important. However, at the same time, the insulation protects the roof waterproofing layer under it from larger temperature-induced stresses and mechanical damage.

Rising components, such as out FLECK flat roof vents and flat roof penetrations, can be extended according to the technical rules for inverted roofs, to take into account the height of the additional build-up layers. If the weighing down is undertaken by green roof structures, we recommend use of our FLECK green roof chamber.

A warm roof describes a roof construction in which no air circulation takes place between the insulation level and the water-carrying layers or the waterproofing. The opposite of a warm roof is a cold roof, in which the air can circulate above the insulation level.

Drainage

The gravel trap is installed above the flat roof gully or drain to protect the drainage pipe from blockages. According to DIN 18531-3, Item 78, the gravel trap is a component that retains coarse solids. It should be cleaned and any deposits removed as part of the regular maintenance to ensure its full functionality. FLECK offers special additional gravel trap modules for the ROOFGUARD, to protect the lift mechanism.

The leaf screen, also called a leaf or gravel trap, is installed above the flat roof gully or drain to ensure a clear drainage pipe at all times. We recommend cleaning the leaf screens as part of the regular maintenance and removing any deposits, so that they remain fully functional. Special leaf screens, such as the innovative ROOFGUARD, have a self-cleaning mechanism. Heavy rain and hail can therefore flow away unhindered, so that the roof is better protected at all times (24/7).

According to EN 12056, a differentiation is made between normal rail events and the so-called one in 100-year event. The drainage capacity of the roof drains and gullies and the wastewater pipe systems are designed for the regularly occurring rainfall events, taking into consideration the geographical location. Additional rain loads, such as those to be expected in a 100-year rainfall event, are additionally discharged via corresponding emergency roof overflows onto open spaces provided for this purpose. An emergency overflow, with and without stop edge, can be installed both in the roof area and in the parapet, depending on the roof type and the drainage capacity. FLECK emergency overflows accordingly match the respective drainage calculation on all flat roofs.

In case of heavy rain that exceeds the normal rainfall, emergency drainage serves to remove the quantities of water from the flat roof quickly so that roofs and the associated buildings survive such rain events without damage wherever possible. When installing emergency drainage systems, in general, round or rectangular emergency overflows are used in the parapet or emergency drains with pipe systems are used. These are responsible for draining the water either into the sewer or onto the site or into soakaways.

Important: Since 1995, emergency drainage on a flat roof is a fixed requirement of the DIN 1986–100 standard.

There are several factors to note when installing emergency drainage. For example, the drained water may not get into the main drainage system, but instead must be discharged via a free outfall onto the site areas that can be flooded without damage. In addition, the emergency drainage system together with the main drainage system must be able to drain the expected one in one hundred year rainfall event at the building location. In the case of buildings with a particular degree of protection, the emergency drainage system must be designed so that it alone can completely discharge a one in one hundred year rainfall event.

The FLECK product range includes different solutions for emergency drainage such as the flat roof emergency overflow in the surface DN 70–DN 150, the flat roof horizontal outlet with 3.5 cm stop edge (emergency spout overflow), the flat roof rectangular emergency overflow, “BIG” or “GIGANT”. To make sure the correctly dimensioned drainage accessories are chosen when designing a new building or renovation, a calculation for the compliant main and emergency drainage should be carried out beforehand.

With gravity drainage the water from a flat roof is removed via gullies and a pipe system laid with a gradient and is discharged into the drain. Gravity drainage uses the principle of gravity and works as follows: The pipes are always partly filled with water. If the water level within the pipes rises to a certain level, the water is flushed into the drain by the gradient in the pipe system. From there it then passes via the main drainage to the sewer or is discharged onto the site or into a soakaway. A gradient is therefore obligatory for gravity drainage. In addition, larger pipe sizes and levels are often required for gravity drainage as they must be filled with water at all times.

In principal, gravity drainage can be used on any flat roof. The number of flat roof drains needed is determined and dimensioned depending on the size of the roof and other parapet areas and wall areas that drain onto the flat roof. FLECK offers a free drainage calculation service for designers and roofers to verify compliant main and emergency drainage. You usually receive the result within two working days after the roof parameters have been completely agreed.

FLECK offers different solutions for gravity drainage: from flat roof gullys to flat roof drains, flat roof renovation drains, flat roof horizontal outlets (spouts) with or without stop edge and flat roof rectangular emergency overflows through to suitable protective devices such as flat roof screens and gravel traps, with and without self-cleaning mechanism.

Siphonic drainage is mainly used for large roof areas, whose downpipes have a minimum height of at least 4.2 metres. The rainwater collects in the individual flat roof drains or gullies and is then drained via a joint collection pipe without gradient into the vertical downpipe. The backed-up and discharging water column causes a negative pressure (vacuum), which enables fast and effective roof drainage with a high flow velocity via the relatively small dimension wastewater pipes. Compared to gravity drainage, in siphonic drainage more aspects must be considered for the drains and the particularly loaded pipe routing. All components only function in the system and must always be precisely matched with each other.

FLECK offers an extensive product range for gravity drainage for new build and renovation projects. FLECK does not currently offer a system solution for siphonic drainage.

Vents

The FLECK 4-in-1 flat roof vent is the all-rounder DN 125 / DN 100 vent for the flat roof. The flange or collar material is optionally made of rigid PVC, bituminous membrane, EPDM and an extensive range of sheeting. As the name reveals, this vent combines four functions in one product: firstly plumbing vent DN 100, secondly plumbing vent DN 125, thirdly renovation vent for a DN 100 vent pipe and fourthly a release vent. If necessary, the weather cap can easily be removed by twisting it off.

The 4-in-1 flat roof vent is also available as versions with condensate separator (KWA) and Flair head and is suitable, for example, for redrying a soaked flat roof insulation layer. Special lengths for the system pipes and thermal insulation can also be supplied by FLECK on request.

The FLECK 4-in-1 system pipes were developed to screw onto the FLECK 4-in-1 flat roof vent. The pipes are available in nominal sizes DN 100 and DN 125, each with or without backflow flap. The integration of the backflow flap during production saves time and costs for roofers, as it no longer has to be installed on site. With the DN 100 or DN 125 system pipes (without backflow flaps), the 4-in-1 flat roof vent quickly becomes the DN 100 or DN 125 renovation vent respectively.

The Aura vent DN 125 is a FLECK pitched roof accessory. This vent can be set plumb and individually on roofs with up to 60° pitch. The Aura vent has an easily removable weather can and can therefore be used in diverse ways. Thanks to the reducer adapter, the nominal size can be reduced from DN 125 to DN 100. It can be optionally delivered with a Flair head.

The Euro fan DN 125 is characterised by its compact design. Due to the easily removable weather cap, it is suitable for venting wastewater pipes as well as for ventilating living spaces. Euro fans, thanks to the reducer adapter, can be reduced from nominal size DN 125 to DN 100 and are available with a large selection of tile types and colours. Other possible uses: slate/shingle and fibre-cement corrugated sheets.

A backflow flap at the outer outlet point of a ventilation duct prevents cold air from flowing in during the winter, or warm air from escaping in an uncontrolled way. A backflow flap is possible and useful in all mechanical extract ventilation systems. Above all, these can be used for poorly ventilated rooms. These include, for example, inner-lying bathrooms, kitchens and recreational rooms in which mechanical air exchange is possible. It is also advisable to install backflow flaps in particular in vents and terminals on the flat roof, as the air ducts to the outside are often significantly shorter there than on the pitched roof and cold air can therefore get into the inside of the building faster.

At FLECK, backflow flaps from DN 100 to DN 150 can be optionally integrated in the following vents/ventilators during production: Aura vents, Euro vents, Sani Extra, Duo plumbing vents, Roof terminals DN 150 or 4-in-1 flat roof vents. Adaptation to the existing pitched roofing is ensued by the individualisation: In the pitched roof segment: FLECK can produce the vent or ventilator for almost 300 roof tile models and paints them to match the colour of the existing clay roof tile or concrete roofing tile.

In the flat roof range, FLECK offers, for example, a large range of suitable flange collars made of bitumen or plastic and elastomeric membranes for the 4-in-1 flat roof vents.

In addition to the energy saving effect, FLECK backflow flaps offer other advantages: For example, among other things, they make it difficult for insects and rodents to penetrate the inside. They also help to prevent condensation, which can form from the warm and humid air removed. The flaps open even with small air currents, so that the connected fans do not have to run at top speed.

Note: Please note that backflow flaps may not be used in vents/terminals on wastewater pipes (stack vent). The negative pressure (vacuum) that can set in during flushing processes in the drainage pipe could make traps easier to draw empty.

The Sani Extra is a popular pitched roof tile ventilator and is used widely. Due to its particularly compact style and attractive, classic design, it is suitable for all standard roof tiles, slate/shingle and corrugated sheets. As the only FLECK pitched roof ventilator, it can be optionally used with a connection pipe socket at 90° (perpendicular to the roof), which can be an advantage, for example, for on-roof insulation systems.

Vapour is a general term used for water vapour saturated exhaust air, which also occurs as fog at higher ambient temperatures and can be additionally mixed with greasy fumes. Vapour is frequently produced by commercial kitchens, bakeries as well as, for example, power stations. Due to the comparably large quantities of air, in these cases, mechanical ventilation systems with diameters DN 150 and larger are often used. FLECK roof terminals are designed for all pitched and flat roofs, in nominal sizes up to DN 500 and if necessary, can be equipped with efficient vent cowls (Flair head) and condensate separators (KWA).

Now use our Roof terminal configurator to determine the roof terminal that suits your personal standards.

Production

Polyethylene terephthalate (PET for short) is a thermoplastic, which most people are familiar with in the form of PET bottles. PETG is a PET modified with glycol, which is characterised by its particularly high transparency and low viscosity. FLECK uses this material to make its transparent tiles, which are thus almost 100% light transmitting.

Polypropylene is the name of a thermoplastic polymer, which is considered to have good heat resistance. In total, polypropylene is one of the most frequently used plastics, especially in the food and automotive industry. Polypropylene flanges are used for roof accessory parts, preferably for the direct joint on FPO/TPO roofing sheets.

PVC stands for polyvinyl chloride, a plastic tried and tested over decades, which is differentiated into PVC-U (rigid PVC) and PVC-P (flexible PVC). FLECK uses PVC-U. By adding special additives, the material can be further refined and adapted to all kinds of different areas of use and requirements. Due to its outstanding thermoplastic material properties, PVC is used in indoor and outdoor construction products. FLECK has been using this versatile material for over 50 years to produce thermoformed roof accessory components for flat and pitched roofs.

Legal requirements and standards

Specific information on lift shaft requirements can be found, for example, in EN 81-20. According to the German Model Building Code (“Musterbauordnung”, § 39 Para. 3, MBO), it must be possible to ventilate lift shafts and they must have a smoke discharge opening with a clear cross-section of at least 2.5 percent of the lift shaft base area, however, not less than 0.10 m². The opening may have a closure, which opens automatically in case of fire and can be operated from at least one suitable place. The position of the smoke outlet openings must be chosen so that the smoke outlet opening is not impaired by the effect of the wind.

Alongside the health and safety regulations, these are building regulation requirements in which architects, design engineers and lift installers find precise specifications in order to design and install lift shaft ventilation properly. Thus, natural smoke control systems for lift shafts can be designed, and ultimately built, correctly according to the building regulations and above all energy-efficiently.

To this end, a specified ventilation opening must be installed. The economic FLECK roof terminals are ideally suitable for ventilating lift shafts (air supply and removal). FLECK roof terminals are designed for pitched and flat roofs in nominal sizes up to DN 500 (1885 cm2), which allows them to be used in a shaft cross-section up to 7.5 m². Ventilation cross-sections up to DN 400 (approx. 1200 cm2) are available for the insulated type. These can be used in lift shafts with up to 4.8 m2 shaft cross-section according to the 2.5% rule. They can, of course, also be adapted to the colour of the surrounding existing roofing.

In Germany, construction products can be classified regarding their fire properties according to the classes described in DIN 4102, into flammable (B1, B2, B3) and nonflammable (A1, A2) construction materials, insofar as no harmonised, European product standards and verification methods can be used. Classification according to the provisions of the European standard EN 13501 (Fire classification of construction products and building elements) is required only for products for which CE marking is planned. This only applies to the following FLECK products: FLECK walkway grating tile and FLECK safety step tile (see the information for the respective products in the download area).

Easily flammable products with construction class B3 to DIN 4102, however, may still not be used in construction. FLECK pitched and flat roof accessories meets the existing requirements described in DIN 4102 for limited combustible B1 or normally combustible B2 construction materials for the roof.

The Construction Product Regulation is a legal regulation of the European Union and the legal basis for the placing on the market and provision of harmonised construction products on the European market. It defines the requirements for the so-called declaration of performance and the CE marking. On 1 July 2013, the CPR replaced the then Construction Products Directive (CPD) issued in 1988. Several changes therefore also resulted for the marking of our FLECK products, since the so-called EC declaration of conformity was replaced by the declaration of performance.

The CE marking documents that the manufacturer meets all the legal requirements for the marked product, which the European community sets for the placing on the market of the respective product. The letters C and E stand for “Conformité Européenne” and mean “European conformity”. A CE marking is attached to those construction products for which the manufacturer must issue a declaration of performance according to the Construction Products Regulation.

If products have to meet high safety requirements, an accredited external test body has to be involved and named (notified body) in the conformity assessment procedure. These can be experts for the respective EU provisions to be applied, for example, such as those found in the TÜV or in suitable test laboratories. As soon as such a product has a CE marking, it may be sold on the European market without hesitation. Safety-related FLECK products are, for example, the safety step tile and the walkway grating tile for pitched roofs. These have CE marking to EN 516: “Prefabricated accessories for roofing – Installations for roof access – Walkways, treads and steps”. The associated declaration of performance can be found in the download area on the respective product pages.

Since 1 July 2013, for each product covered by a harmonised European standard (hEN) or a European Technical Assessment (ETA), manufacturers are obliged to provide or transmit a declaration of performance in printed or electronic form to the trader, and they in turn the installer/user) for each of their products that fall under the Construction Products Regulation (CPR). The Declaration of Performance under the CPR replaced the previously applicable EC declaration of conformity and is the equivalent of a certificate. Among other things, it includes:

- a reference to the type of application of the construction product

- information on the method or system applied, by which the construction product was tested

- Information on the harmonised EU standard (incl. publication date), which was used to assess the essential characteristics

- Information on the minimum requirements met by the construction product

In Germany, compliance with the regulations regarding CE marking and declaration of performance is controlled by so-called market surveillance, which is the responsibility of the Federal States. The market surveillance authorities of the states carry out random checks on site, for example, in DIY stores, in trade suppliers/traders or at customs. The Deutsche Institut für Bautechnik in Berlin (DIBt), as the joint market surveillance authority of the Federal States, among other things is responsible for central coordination. On the website of the DIBt you will find further and always up-to-date information on the Construction Products Regulation, declaration of performance, CE marketing and market surveillance.