Questions about ECO FORM EASY

ECO FORM EASY is made from the particularly resistant basic material PVB (polyvinyl butyral) and is chemically extremely stables, which is why it is used, among other things, to produce roof waterproofing sheets. PVB is also neutral to bitumen and copper. This applies not only to direct contact with bitumen and copper but also to impinging rainwater from bitumen and copper surfaces.

Polyvinyl butyral (PVB) has been successfully used by Leadax for many years to manufacture a sustainable lead substitute in different forms. Tests on long-term weather influences have been and are carried out by the manufacturer Leadax in the accredited laboratories of KIWA.com. The tests already carried out confirm a simulated use period of 30 years and more.

No. ECO FORM EASY is produced in a specially developed production method, in which the expanded aluminium is prepared and then completely moulded in. It thus consists of homogeneous PVB overlays on both sides, which are permanently joined together through the expanded metal openings. The expanded metal is responsible for the deformability and the load absorption and distribution, while the more resilient PVB layers ensure permanent leaktightness. This build-up with its respective functional layers ensures long use, e.g. on weather-exposed roofs. Nonetheless, it offers the possibility of re-separating these layers industrially after decades of use, in order to recover them in a recycling method.

This is not to be assumed as long as the areas with voids under them are not excessively loaded. The rain and snow loads that occur in Europe are not a problem here. The stable aluminium expanded metal easily absorbs such loads. Subsequent deformation is very unlikely if the voids are kept small. However, areas with voids under them do not provide adequate protection against damage that can be caused local impact loads, e.g. due to falling roof tiles, heavy or pointed tools, etc. We therefore recommend avoiding areas with voids under them or keeping them as small as possible.

ECO FORM EASY has two self-adhesive butyl adhesive strips. These are used to fix ECO FORM EASY and facilitate shaping it to the flashing components. In addition, the adhesive strips also form protection against slipping or lifting off. In addition, ECO FORM EASY can also be permanently welded by using suitable hot air blowers as used, for example, for flat roof waterproofing sheets. To this end, the butyl adhesive tapes attached on the back can be detached before welding in the bonding areas.

Questions about the FLECK Flair head

The task of the Fleck Flair head is to achieve the largest possible air passage so that mechanical ventilation systems can develop the best possible effect. The air is blown out in a vertical jet and therefore contamination and odour nuisance are reduced near the Flair head and the roof covering.

Fleck Flair heads follow the technical principle of a deflector hood and function as extract air cowls. Deflector cowls are the most commonly used cowls for discharging used air containing contaminants in the roof area. They are used in ventilation and dust removal systems where the exhaust air must be blown out into the outside air as high as possible, so that it mixes with the ambient air and is therefore diluted. These cowls are designed with a very high outlet velocity, which means a very large throw is achieved, while the pressure loss is kept within reasonable limits. A deflector cow’s characteristic shape is due to the inner-lying rainwater discharge, which is wider than the exhaust air opening. If a roof were to be used as rain protection instead of the deflector cowl, the exhaust gas plume would discharge at the side and thus rise less.

Its structure is essentially explained by its function as protection against the penetration of precipitation (snow, rain) into the ventilation system:

- Konstruktiv bedingt sind Flairköpfe von FLECK nicht mit sogenannten Wetterkappen oder Regenhauben ausgestattet. Diese sind bzgl. eines Regenwasserschutzes auch technisch nicht notwendig, weil die Produkte von FLECK den Regenwassereintritt durch die integrierte Auffangschale verhindert. Hier wird das Regenwasser gesammelt und über den Ablaufstutzen auf die Dachfläche geleitet.

- Als zweite zusätzliche Sicherung werden bei FLECK Lüftungsrohre bei Verwendung eines Flairkopfes in den Flairkopf eingearbeitet, so dass eine zusätzliche Entwässerungsebene („Regenrinne“) entsteht. Das hier aufgefangene Wasser (Regen, Schnee oder Kondenswasser) wird durch eine zweite, etwas tiefer im Flairkopf angebrachte Öffnung auf die Dachfläche abgeführt.

The Flair head must be installed plumb so that it can develop its effect. Its drainage openings must also be kept clear.

Details of the pressure loss of the Flair head for the design of ventilation systems are provided in the FLECK product data sheets, which can be found on www.fleck-dach.de.

Questions about flat roofs

Puddles small in size and number can remain on flat roofs. Waterproofing with polymer bitumen sheets provides sufficient protection. In the event of large and deep puddles, the waterproofing in these areas must be checked regularly as part of the maintenance. When renovating or renewing a non-sloping roof, we recommend creating a slope, for example, using sloped insulation.

Questions about flat roof drainage

Emergency drainage ensures that in case of a heavy rainfall event, flat roofs survive it with as little damage as possible. It has been a fixed requirement of the DIN 1986–100 standard since 1995 and since then, must always be provided in addition to the main drainage system when designing drainage systems. In general. round and/or rectangular openings are made in the parapet for emergency drainage or emergency outfalls via pipe systems are installed, which either discharge the water into the sewer or onto the site or into soakaways.

FLECK has different solutions on offer for emergency drainage:

Emergency drainage must be able to absorb and remove the additional quantities of water in case of particularly heavy rainfall events such as one in one hundred year events. In the case of buildings with particular protection requirements, the emergency drainage must be able to completely remove the quantity of water of a one in one hundred year rainfall event. Here it must always be borne in mind that the water discharged from emergency drainage must not be allowed to get into the main drainage system, but instead should be discharged onto open spaces on the site, which can be flooded without causing damage.

FLECK has the following products in its product range for emergency drainage:

With gravity drainage the water from a flat roof is removed via gullies and a pipe system laid with a gradient and is discharged into the drain. Gravity drainage uses the principle of gravity and works as follows: The pipes are always partly filled with water. As soon as the water level within the pipes rises to a certain level, the water is flushed into the drain by the gradient in the pipe system. The water then passes via the main drainage to the sewer or is discharged onto the site or into a soakaway. Accordingly, gravity drainage cannot work without a gradient. In addition, larger pipe sizes or levels are often required due to the permanent water level.

FLECK’s product range has different solutions for gravity drainage:

In siphonic drainage, the rainwater of the individual flat roof gullies or drains collects in a joint discharge pipe without gradient and is then removed via a downpipe at least 4.2 metres high. The resulting negative pressure (vacuum) caused by the backed-up water column results in fast and effective drainage of the roof surface with high flow velocity. Compared to gravity drainage, in siphonic drainage more aspects must be considered for the drains and the particularly loaded pipe routing. This is because the components only function in the system and must be precisely matched with each other.

FLECK does not currently offer a system solution for siphonic drainage.

Siphonic drainage is mainly used for large roof areas, for which the downpipe of the drains is at least 4.2 metres high.

Thanks to the physical laws of negative pressure, the collection pipes that have to be particularly stable and tight do not have to be laid with a gradient. In addition, siphonic drainage has a self-cleaning effect due to the high flow velocity.

Questions about the FLECK vents and ventilators bzw. der Dachentlüftung im Allgemeinen

Roof ventilation can be differentiated into the following applications.

- Ventilation of living spaces

- Venting wastewater pipes

- Ventilation of closed roof spaces (attics)

- Ventilation of lift shafts

Decentralised and central ventilation systems are used to ventilate living spaces. These require supply air and exhaust or extract air devices, which are installed in the façade or on the pitched or flat roof. With the FLECK vent/ventilator range, the ventilation can be provided in diverse ways and according to the requirements of the ventilation system. Vent dimensions up to DN 500 can be used for this. Additional products such as condensate separators, additional thermal insulation or Flair heads also provide a useful addition to mechanical extract air systems, particularly if the extract air is heavily loaded with vapour.

DIN 1986-100 requires that wastewater pipe systems be extended to above the roof for ventilation purposes and must be open at the top. This removes unwanted pressure fluctuations and sewer gases via pitched or flat roof vents or ventilators. A wide range of FLECK vent and ventilator products can be drawn upon for all possible application cases on pitched and flat roofs. Vent products with easy to remove vent caps are preferably used here. Condensate separators are not required because condensation can easily drip into the wastewater pipe systems.

Uninsulated roof spaces (attics, boxrooms, flat roof cold roofs), which are sealed airtight with the outside, e,g, by vapour retarders or underlay sheets, should be additionally ventilated to avoid the formation of harmful condensation. The formation of excessive condensation frequently leads to structural damage (wood rot, wet components with mould). If this cannot be easily implemented in the design, additional vents or ventilators installed on the pitched or flat roof can provide more safety. The vents/ventilators therefore form the connection between the outdoor air and the closed rooms and carry out the necessary air exchange. It must be ensured that at least two vents/ventilators are set for the supply and exhaust/extract air for each closed room, and they must penetrate the airtight outer skin. It must be ensured that both the number and the size of vents are adequately dimensioned. According to the generally recognised rules of good engineering practice, on a flat roof it must be ensured that the ventilation openings are located in two opposite sides.

According to the building codes of the Federal States, it must be possible to ventilate lift shafts to balance pressure. This is often done, for example in commercial buildings, by providing large grille openings in the façade. In many cases, the ventilation is designed for installation above the roof for design or architectural reasons. At the same time, it must be ensured that the ventilation areas of the planned vents/ventilators is at least 1,000 cm2 or 2.5 % of the lift shaft cross-section. FLECK offers flexibly designable products for this, for both pitched and flat roofs, up to DN 500. The weather caps supplied are designed so that the outlet cross-sections at least equal the cross-sections of the connected ventilation ducts and do therefore not cause any obstacle to the air flows. An appropriate FLECK flat or pitched roof vent with external diameter DN 500 (internal cross-section = 1885 cm2 = 0.1885 m2) can ventilate a lift shaft up to 7.5 m2 in conformity with the building regulations. If applicable, fire protection aspects must be additionally considered when choosing the systems.

Information on the ventilation area of specific external outside and internal pipe diameters of our products for the design of ventilation systems is provided in the pipe table under Downloads. Our vent heads that are preassembled in the factory are fitted with a weather cap so that, regardless of the wind direction and intensity, the ventilation duct or the air duct is protected from penetrating precipitation (rain, snow, hail).

Due to the inlet and outlet openings made with the FLECK-specific shape, our vent heads (apart from the so-called Flair head) can be used for both the supply (external air) and for the extract air (exhaust air). In the vent head designs developed by us, we always took care not to reduce the respective ventilation area of the pipe. The calculated ventilation area of the respective head diameter is given in the following list:

- DN 50 – 20 cm²

- DN 70 – 50 cm²

- DN 100 – 126 cm²

- DN 125 – 148 cm²

- DN 150 – 200 cm²

- DN 200 – 300 cm²

- DN 250 – 480 cm²

- DN 300 – 836 cm²

- DN 400 – 1275 cm²

- DN 500 – 1980 cm²

Other quality characteristics of the vent heads and products are described on the associated product data sheet and other technical information, which can be found on our website under Downloads. The respective current version of our General Terms of Payment and Deliver (GP&D) apply and can also be viewed there.

Before installing, always remove the cardboard sleeve at the end of the universal hose, provided to protect the dimensional stability. The flexible hose is first put on over the connection socket of the roof tile and is fastened using the hose clip supplied.

At the other end of the hose there is a stepped reducer, with which the diameter can be optionally tapered to DN 70, DN 100 or DN 125. The reducer can be easily adapted to the connecting pipe as required by cutting off the smaller steps.

When laying the flexible hose, note that the inserted reducer and the flexible hose must be laid as vertically as possible. Possible condensate accumulations in the flexible hose are avoided as a result. Further information can be found here.

Under certain circumstances, water vapour from the vent pipes can cause ice to form on the pitched roof vents at below zero temperatures. This effect can occur in all our pitched roof vents and ventilators, for example, Extra plumbing vent DN 100, Aura vent DN 125 with standard head, Euro vent DN 125, Duo plumbing vent DN 125 or Saniflex universal ventilator DN 100 for PV arrays.

The functional capability of the fan/ventilator is not impaired in any way whatsoever as a result of this. The icing is not a defect. When there are large temperature differences between the temperature inside and the outdoor temperature, from a building physics view this is unavoidable with use of the fans/ventilators listed above, albeit not harmful.

The icing can be minimised by using FLECK Flair heads. FLECK Flair heads follow the technical principle of a deflector cowl and function as extract air cowls. The following FLECK products can be equipped with a Flair head: Aura vent DN 125 and Auraflex universal vent DN 125/DN 150 and roof terminal DN 150/DN 200.

Deflector cowls are the most commonly used cowls for discharging used air containing contaminants in the roof area. They are used in ventilation and dust removal systems in which the exhaust air must be blown out into the outside air as high as possible, so that it mixes with the ambient air and is therefore diluted. These cowls are designed with a very high outlet velocity, which means a very large throw is achieved, while the pressure loss is kept within reasonable limits.

The characteristic shape of the deflector cowl is due to the inner-lying rainwater discharge, which is wider than the exhaust air opening. If a roof were to be used as rain protection instead of the deflector cowl, the exhaust gas plume would discharge at the side and thus rise less.

The FLECK Flair head also has the tasks to achieve the largest possible air passage so that mechanical ventilation systems can develop the best possible effect. The air is blown out in a vertical jet and therefore contamination and odour nuisance are reduced near the Flair head and the roof covering.

Its structure is essentially explained by its function as protection against the penetration of precipitation (snow, rain) into the ventilation system:

- Due to their design, our Flair heads are not equipped with so-called weather caps or rain covers. These are also not necessary technically in terms of rainwater protection, because our product prevents rainwater from entering through the integrated drip pan. The rainwater is collected here and is discharged onto the roof via the outlet sockets.

- As a second additional protection, the ventilation pipe is incorporated in the vent head so that an additional drainage level (“rain channel”) is created. The water collected here (rain, snow or condensation) is discharged through a second opening made somewhat lower and onto the roof.

FLECK underlay sealing collars seal penetrations of vent pipes through a water carrying underlay.

They ensure that water discharging above the underlay (condensation, melted water from drifting snow) is removed safely past the penetration.

This prevents possible local saturation of the level below the underlay sheet in the area of the penetration and the associated moisture damage.

Questions about FLECK transparent tiles

A so-called “burning glass effect” cannot occur in our transparent tiles. To this end, the tiles would have to be set up like a convex lens over a large area.

The surfaces of our transparent tiles are either parallel flat or parallel curved relative to each other, which means that concentration of light on a sharply formed focal point is ruled out.

FLECK transparent tiles are suitable for both individual and extensive laying (transparent roof). FLECK recommends laying alternating transparent tiles and roof tiles, because this achieves a particularly favourable ratio between light incidence, number of tiles and illumination of the hall areas below.

The number of illuminated tiles also determines the light intensity that can penetrate through the roof into the hall.

Where possible there should be no shading caused by rafters, purlins, collar ties below the transparent tiles.

Questions about FLECK roof solar accessories

The design load for FLECK solar carrier tiles with a partial factor of y=1.3 is:

- Normal force component = 4.6 kN

- Vertical force component = 1.5 kN

With roof pitches 0°, 15°, 60° and 90° degrees the test forces are as follows:

- 0° -> 6 kN

- 15° -> 5 kN

- 60° -> 1.8 kN

- 90° -> 1.9 kN

Other quality characteristics of our products are described on the respective associated product data sheet, which can be found on our website under Downloads. The respective current version of our General Terms of Payment and Delivery (GP&D) apply and can be viewed there.

In the case of plain tile roofings, a differentiation is made between crown roofing and double roofing. Our Solarflex universal support tile is currently not suitable for either type of roofing. FLECK is working on a solution.

Questions about ROOF SUPER DRY

With our ROOF SUPER DRY absorber granulate, work on the flat roof can be carried out even if there are problematic water puddles to be removed – without having to dry the whole area first. The drying powder is sprinkled directly into the water, for example, in a circle around the area to be worked on and swells within a few minutes to up to 200 times its own volume. The quantity of water in the work area is completely absorbed and a solid dam of gel forms, which prevents further water from flowing into the area. The ROOF SUPER DRY activates as soon as it is sprinkled into the puddle and can be used for at least an hour. With the new ROOF SUPER DRY, many subsequent jobs on the roof, such as inserting a FLECK flat roof gully, the installation of a flat roof gooseneck or the installation of a FLECK 4-in-1 flat roof vent can be carried out quickly and inexpensively. The gel is then simply disposed of, e.g. in the household waste.

ROOF SUPER DRY can also be used for repair work on roof gutters by making a temporary dam to hold back water. The granulate can be used wherever water and moisture must be kept out of the actual work area.

Note: The recommended working time is max. 4 hours (or faster). Then remove all the gel residues from the roof and clean the work area thoroughly.

Questions about products with heat-shrink sleeve

The “Schrumpfi” with heat-shrink sleeve is usually pushed directly over the existing cables, pipes or socket. The flange or flange collar is then properly bonded onto the roof waterproofing level. The loosely supplied and weather-resistant heat-shrink sleeve is coated on the whole of the inside surface with a hot melt adhesive. On shrinking on with a hot air blower (air gun), the hose shrinks and after cooling, the melted adhesive forms a permanent watertight bond with the flange body and the individual penetration product.

On heating, make sure that the hose is shrunk on properly on all sides and always from the bottom up. A video showing correct use and installation can be found on our YouTube channel.

Schrumpfis are particularly recommended for single line penetrations of all types such as single cables/pipes, for example, of a photovoltaic or solar heat system. In case of bundled cables or pipes, the FLECK goosenecks with sealing collar can be used.

Questions about pitched roofs

Standard roof pitch is the name used for the lowest roof pitch at which a laid roofing material is still adequately rainproof.

Minimum roof pitch describes the smallest roof pitch at which rainwater is still removed from the roofing.

Unlike roof waterproofing (membranes), roofings cannot be absolutely watertight (water resistant). The “rainproof” requirement means that the roofing must protect the building from normal rainfall events.

Questions about FLECK products

Most of our products are made of plastic parts that are produced in-house by injection moulding, extrusion or deep drawing (thermoforming). PVC granulates or PVC sheets are used as starter material. PVC is an abbreviation of polyvinyl chloride. This is a thermoplastic polymer, which is produced from the monomer vinyl chloride by chain polymerisation. PVC plastics are divided into rigid and soft PVC. Soft PVC (PVC-P for short, where P stands for plasticised) contains plasticisers, which provide the elastic behaviour of the material. For example, it is used for cable sheathing and floorings. Rigid PVC (PVC-U for short, where U stands for unplasticised) does not contain plasticisers. The vast majority of the parts assembled to form finished products in our range are made of rigid PVC (PVC-U). Further information about the plastic PVC can be found on the website of the industry’s network “Vinyl plus” (“Arbeitsgemeinschaft PVC and Umwelt e.V.”, Bonn (AGPU): www.agpu.de

The fire behaviour or reaction to fire of FLECK products is classified according to DIN 4102 or EN 13501. They at least correspond to the building inspectorate name “normally flammable construction material”. The respective building codes of the individual Federal States or special building regulations and other relevant standards set out when and to what extent construction materials classified as “normally combustible” can be used.

For example, § 26 of the building code of the State of North Rhine-Westphalia (NRW) specifies that construction materials that are not at least normally combustible (easily flammable construction materials), may not be used. Other quality characteristics of our products are described on the respective associated product data sheet, which you can find on our website under Downloads. The respective current version of our General Terms of Payment and Delivery (GP&D) apply and can be viewed there.

Further information on the construction material class can be found in our glossary.

The following proofs for our products are not possible according to the provisions of the Deutsches Institut für Bautechnik in Berlin (DIBt):

- National technical approval (NTA)

- National test certificate (NTC)

For this reason, we can also not provide you with any test reports related to approvals or approval tests or similar.

Background: The German control system for construction products and techniques is defined in the 16 Federal state building codes. The State building codes are based on a joint model, the Model Building Code (MBO).

The State building codes also define the permit and approval procedures for construction products and techniques. The requirements for buildings and structures generally defined in the State building codes are specified in greater detail by the Technical Building Regulations of the Federal States. There is also a joint model for this, namely the Model Administrative Regulation Technical Building Regulations (MVV TB). Which version of the technical building regulations is implemented or applicable in which federal state can be seen on the website of the DIBt.

The Model Building Code and the Model Administrative Regulation Technical Building Regulations are thus used as a template for the relevant state regulations. The building codes basically differ between the following regulatory verifications of fitness for use for construction products: abZ (national technical approval, NTA) and abP (National test certificate for a construction product). However, an abZ is not required if the construction product is listed in the MVV TB Part D 2 (construction products, which do not need any regulatory verifications of fitness for use) or for which generally recognised rules of sound engineering practice exist for the construction product. This applies to us: On the one hand, one part of our products falls under sections 2.2.5.2 and 2.2.3.12 of Part D 2 of the MVV TB. On the other hand, generally recognised rules of sound engineering practice apply to these.

And an abP is issued for construction products and techniques that can be evaluated according to generally recognised test methods. These products are finally listed in the technical construction regulations. However, our products are not included in this list.

The quality characteristics of our products are described on the respective associated product data sheet, which you can find on our website under Downloads. The respective current version of our General Terms of Payment and Delivery (GP&D) apply and can be viewed there.

For diverse FLECK products such as the safety step tile and the walkway grating tile for pitched roofs, both a declaration of performance and a CE marking are available. Further information on the legal provisions is also provided in our glossary under CE marking, Declaration of performance, Construction Products Regulation (CPR) and Market surveillance.

Questions about the ROOFGUARD

The ROOFGUARD can be installed on all flat roofs with gravity drainage and on for roof drains (gullies) with pot diameters of 60-200 mm.

The emergency release of the ROOFGUARD takes place at approx. 65 mm backed-up level and provides protection against flooding and excessive loads, for example, due to hail or accumulated leaves.

The ROOFGUARD is released in case of roof gullies blocked by leaves, hailstorm followed by rainfall and blocked pipes and thus always takes care of clear runoff on the flat roof.

The backed-up level of 65 mm provides sufficient water pressure to flush the leaves through the pipe together with the water. At a water level of approx. 30 mm, the ROOFGUARD returns to its home position and the screen is closed again.

The ROOFGUARD can freeze, however, during frost there is no liquid precipitation. The waste heat from the outlet pipe enables the gully and the screen to become frost-free first, in addition, the gully can be heated if necessary.

A ROOFGUARD can be installed on a gravel or on a green roof with the optionally available gravel trap. The add-on module prevents substrate and gravel from being washed into the ROOFGUARD, so that it also functions faultlessly on these roofs.

Together with the optional parapet extension module, the ROOFGUARD can also easily be installed on a parapet gully. The optional extension modules can be purchased separately from FLECK.

As with almost all gravel traps/leaf screens, the drainage rate increases with the level of the backed-up water and the drainage capacity is often only limited by the friction in the outlet pipe and the turbulences that set in. Therefore, in the relevant generally recognised rules of good engineering practice, a partial fill of 70 % is given (DIN 1986-100: degree of fill of h/di = 0.7). In addition, a requirement is for the joints to be kept tight against an internal pressure of at least 0.5 bar (5 metre water column) and secured against movement (DIN 1986-100).

A water column of 5 metres (0.5 bar) is actually not possible in a house, as the vertical distances between the floors (toilet to toilet) are < 3 metres in most cases. Water that has backed up due to pipe blockages would therefore soon emerge sooner.

When choosing the outlet pipes, possible backed-up water at full height (halls > 5 m) must be taken into account in the designs and the pipes designed accordingly. A corresponding design does not affect the function of the ROOFGUARD at all.

The ROOFGUARD can naturally also be used on an inverted roof. The following must then be noted:

In general, the insulation on an inverted roof is made of waterproof XPS insulation boards. These are based on the basic material styrene and are not compatible with the Alsan 074 adhesive.

For this reason, the bonded surfaces must be appropriately pretreated.

Solution: The simplest way to prepare the planned installation areas is with, e.g. a bituminous membrane with slate granule surface and a suitable PU adhesive.

The ROOFGUARD can then be fixed on the bitumen membrane areas, as described in the laying instructions, with the Alsan 074 adhesive paste.

As the inverted roofs must be executed as gravel or green roofs for weighing down purposes, we recommend using the plug-in additional ROOFGUARD gravel trap module.

If the ROOFGUARD is blocked by a branch lying on it, but the integrated leaf screen is still clear, the ROOFGUARD functions as a normal leaf screen. Only the self-cleaning mechanism is then possibly blocked. To prevent this, as required in the technical regulations, maintenance should be carried out on the flat roof areas and installations at regular intervals. In this way, the faultless functioning of the ROOFGUARD can always be assumed.

No, the ROOFGUARD functions purely mechanically and does not need an external power supply. The self-adjusting emergency drainage system releases as soon as a backed-up water level of more than 60 mm forms in the area of the ROOFGUARD. The screen lift mechanism then makes shore that the leaf screen rises. The available pressure of the flowing in water flushes the screen clear and ensures a clear outlet. Accumulated leaves or hail is flushed through the pipe and removed.

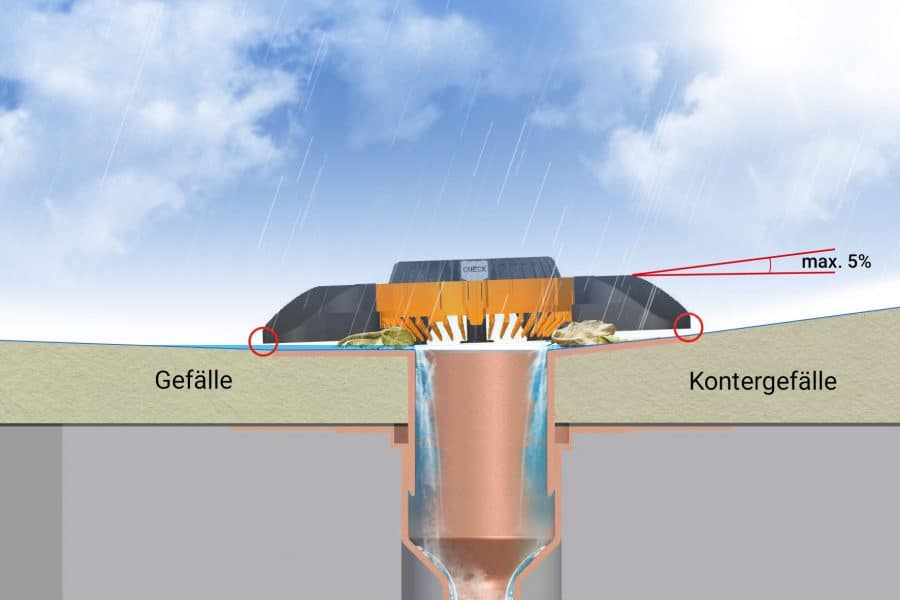

The ROOFGUARD is generally suitable for use on a flat roof. A flat roof usually describes a roof with a roof pitch of less than 10 percent. Tapered roofs (flat roof with tapered insulation boards) generally have a slope of two to five degrees. A ROOFGUARD can also be easily installed at this roof pitch. In general, the drainage always takes place at the lowest points of the sloping roof. This area around the drain is unfortunately not always completely level, which can lead to additional measures when installing the ROOFGUARD. Before laying the roof waterproofing, the area around the drain is often sunken into the insulation level. If this was not done, the three feet of the ROOFGUARD can be aligned with the thickly applied adhesive paste so that it can be positioned as horizontally as possible over the drainage opening. Alternatively, before using the adhesive paste, properly carried out doubling of the lower lying area (secure connections of the individual layers against tensile forces) can be used to make an appropriate surface.

For a roof build-up with additional, steeper sloped counter-slope to the parapet, under certain circumstances, the situation can occur that the ROOFGUARD is slightly sloped after installation. This is not a problem, since in this situation the ROOFGUARD still releases if the backed-up water level is higher than 65 mm. The slope should not be more than 5 percent maximum.

Important: The three black floating bodies should always be able to work freely and therefore not touch the roof waterproofing.

The ROOFGUARD is made of high-quality ASA Luran S 757G, a plastic that has been tried and tested outdoors and can be used on the roof for years. Usual weather influences such as rain, hail, wind and UV radiation can also not damage the material long-term. This ensures sustainable use.

A special 2-component adhesive paste that is included ensures permanent bonding between the ROOFGUARD and the roof without having to penetrate the existing roof waterproofing levels. To achieve this, the roof surface is thoroughly cleaned or pretreated first and slightly ground if necessary. In the next step, only the ROOFGUARD screen without the floats is installed first. To this end, the adhesive paste is mixed with the activator powder and the mixture is then spread on the underside of the three base feet (Important: note the marked bonding zones!). The screen, centred above the roof gully, is then bonded by pressing on it lightly. Surplus adhesive residues should be removed to prevent the floats from being impaired. After approx. 20 minutes the adhesive has reached sufficient initial strength for the three float bodies to now be installed: these are simply uniformly pressed onto the planned places on the screen from above until they latch into position with a quiet click.

In order not to penetrate or damage the roof waterproofing level, we recommend installing the ROOFGUARD with the adhesive supplied. The special 2-component adhesive paste ensures a permanent bond between the base feet of the ROOFGUARD and the roofing sheet laid and therefore ensures long-term use on the roof.

As an alternative to adhesive installation, the ROOFGUARD can also be secured with the help of welded on straps which hold the feet in position. To this end, only three adequately dimensioned straps made of the same material as the laid roofing sheet must be made. These straps are positioned above the feet and are welded onto the existing roofing sheet so that the ROOFGUARD can no longer be moved.

No, quite the opposite: the drainage capacity of the gullies is in fact improved by the ROOFGUARD. Reference measurements of a DN 70 drain with universal gravel trap compared to the ROOFGUARD have shown that the water always flows away more strongly. At a backed-up level of a good 65 mm, the drainage capacity was increased by approx. 2 litres per second. An overview of the drainage capacity of our FLECK drain systems can be found here.

To visually inspect and clean the gully regularly, the black, top inlet part of the ROOFGUARD can be removed by undoing the three retaining screws so that the drain is exposed. The float bodies of the ROOFGUARD can also be dismantled at any time.

It functions so simply:

- Remove the check indicator, positioned on one of the three openings on the leaf screen.

- Insert and turn the check indicator to release the locking between the float bodies and leaf screen.

- Push the check indicator in the direction of the leaf screen until it latches into position.

- Grip both sides of the float body and remove it from above.

- Repeat the process for all floats.

- After the inspection or cleaning, the float bodies can be re-attached in the reverse order.

Click here for detailed installation instructions.

With little effort, the ROOFGUARD can be used on all flat roofs with gravity drainage and can be installed above roof drains with a pot diameter of 60-200 mm. It can also be retrofitted at any time and can be complemented with gravel trap elements on green roofs or gravel areas:

The ROOFGUARD is not suitable for use in a pressure drainage system.

The number of ROOFGUARDs needed on a flat roof depends on the number of roof gullies or drains. It is possible to place a ROOFGUARD on each gully/drain up to DN 200 because only a free drain can ensure sustained drainage. This applies to hail just like for soiled leaf screens. In particular, drain points that are affected by leaf waste particularly frequently should be preferably equipped with a ROOFGUARD. This also applies to drains through the parapet, since here the ROOFGUARD parapet extension provides the appropriate safety.

Questions on solar obligation in the Benelux countries

The following overview has been compiled from publicly accessible media to the best of our knowledge and belief, nonetheless, no claim is made that it is correct and complete.

You therefore only acquire legal certainty if you receive advice from a legally qualified source.

Dated: May 2023

Until now, only one region of Belgium, in Flanders, has opted for the solar obligation. In the other Belgian regions of Brussels and Wallonia, and in the Netherlands and Luxembourg, specific plans regarding a solar obligation have not (yet) been announced.

The following overview has been compiled from publicly accessible media to the best of our knowledge and belief, nonetheless, no claim is made that it is correct and complete.

You therefore only acquire legal certainty if you receive advice from a legally qualified source.

Dated: May 2023

The Flemish government has decided that by 30 June 2025, solar modules are mandatory for buildings that are connected to an energy extraction point (so-called EAN acceptance point), with a power consumption of more than 1 gigawatt hour per year. This threshold value applies from 2021. The area of the solar modules must be at least 10 percent of the total horizontal roof area. In addition, successive expansion of the system is planned: at least 15 percent of the roof area must be equipped with solar modules by 2030, and at least 20 percent by 2035. The owners, leaseholders or users of the buildings connected to the energy extraction point must meet the obligation. It is possible for multiple building to be connected to this extraction point. In this case, the owners, leaseholders and users together are obliged to erect the solar system on one or multiple roofs. In addition, it is also permitted to install the solar modules on the site of buildings used by the majority and on one or multiple carports or bicycle stands, “perimeter areas” such as roadsides or closed landfill areas that are not designated as nature conservation or agricultural areas and on water. Other rules apply to public organisations, as they have a model function: If public corporations are the sole owners, leaseholders or users of the building connected to the EAN acceptance point, the PV obligation applies from a purchase of more than 250 megawatt hours/year (MWh/a). From 2030, the obligation will be extended to include buildings that are connected to an EAN consumption point, at which a consumption of more than 100 MWh/a is registered from 2026.